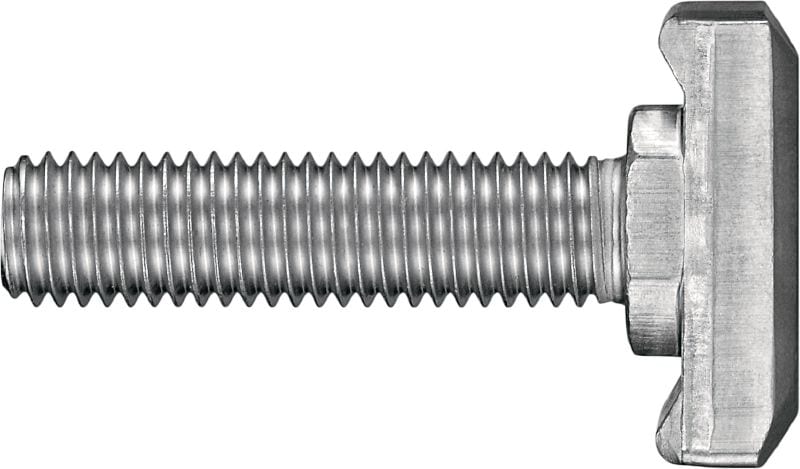

This perpendicular bean gives the threads the full thickness of a stud to screw into as it would in a residential wall. The perpendicular 3.5 inch beam was only pre-drilled for the traditional lag bolt, as the other three did not require it. I also used the same 5/8" washers with all bolts. I pre-drilled the 1.5 inch thick top beam so that it woud not grep any of the threads. I assembled them perpendicularly to form a t-beam, but with a 5/8 inch spacer between to create a gap in which I could measure deflection. What's the maximum percent of a structural member's profile you'd want to drill out to install a bolt before you'd worry about reducing the strength of the member? For instance, I'm sure it would be self defeating to install a 1.25 inch diameter lag bolt in a 1.5 inch wide stud, even dead center, because the remaining wood would be so weak you could sneeze it in half. If I was a half inch inch off from center, and drive a half inch bolt, it probably would pop out the side of the stud, right? I could be off a bit if the wood has knots or the 2x4's are less than perfect.Į.g. And mine are hidden behind drywall on both sides, so I'm not confident that I can hit them exactly centered. I want them large enough to handle hundreds of pounds of shear and tensile load, but small enough that I don't significantly weaken the 2x4 itself.Ģx4's are only 1.5 inches wide. I will try and shoot a video to explain the scenario and why spring nuts would not work for this.I will be fastening Unistrut vertically along studs to facilitate garage storage, and want some guidance on choosing the "best" lag bolts to use. And you could not get a 1/2" nut inside a piece of 1/2" Unistrut nor the head of a 1/2" Hex nut.there is simply not enough room.as you can see here between the 2 blue arrows.Īnd even if you could get a bolt in there? (Which you cannot) You could not hold the head after the Unistrut was mounted.and even if you could? (Which you cannot) You would have to figure out how to mount the whole thing to a carriage bolt because that was the criteria in the first place. Now since the filter unit needed 1/2" bolts? And I wanted to use 1/2" Unistrut? There is no such thing as a 1/2" spring nut for 1/2" Unistrut. They are 1/2" corse thread bolts as you can see by this picture.

The size of the bolt was determined by the weight of the filter unit itself and the size of the filter mounting holes. Anything other than a nice rounded head of a carriage bolt would leave a place for the dust or paint or clear residue to gather on the inside of the booth. Remember I did not mount these to a wall. Ok the criteria for the 1/2" Unistrut was to have a carriage bolt top on the inside of the paint booth as opposed to a hex head or even the threaded portion of a 1/2" bolt showing on the inside of my paint booth. 173 Part Preperation, Primers and Adhesion Promoters.

0 kommentar(er)

0 kommentar(er)